Official Assignment Description: 'update your final project plan:

-what will it do?

-what's been done before?

-what will you need to develop?

-what will be done?

-what materials and components will be needed?

-what will it cost?'

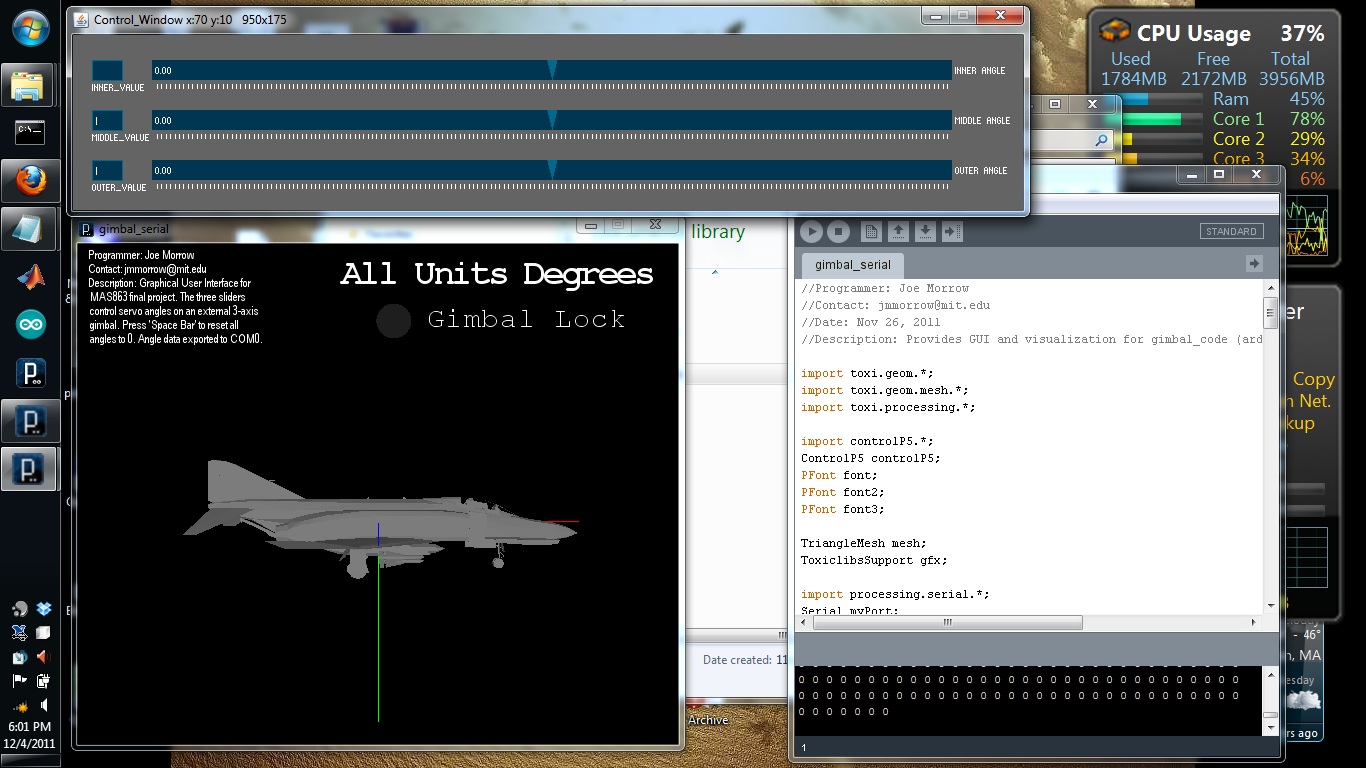

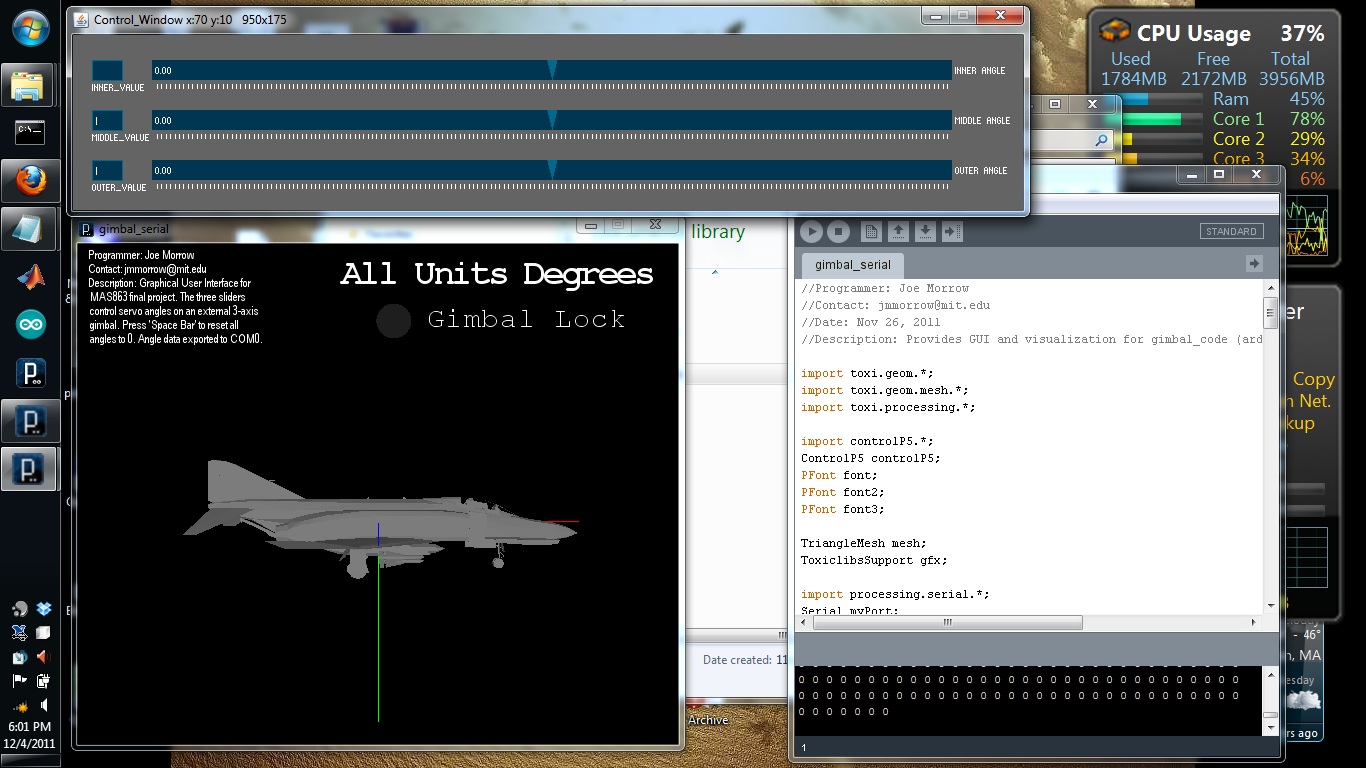

At this point I am well into the development of the 3-axis gimbal mechanism. It is designed to help me visualize air and spacecraft orientations. It will be able to operate independently from a 9V wall wart and controlled via potentiometers; it will also be able to connect to a computer with a serial connection and controlled via the GUI created (in Processing) last week.

This type of device has certainly been conceived in the past, but visualization is usually accomplished with computer simulation only. Gimbals themselves are well-understood, but are difficult to make because they tend to require careful design and construction to in order to function well. They are often made out of steel or aluminum.

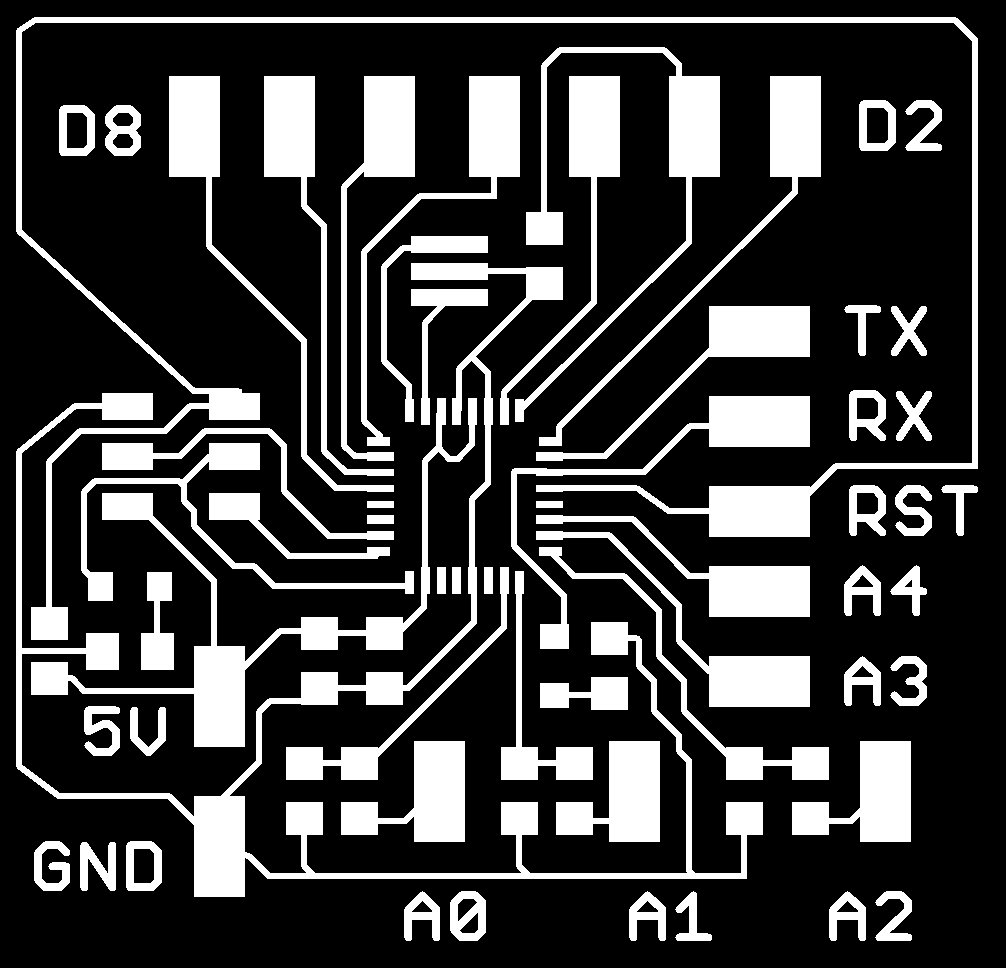

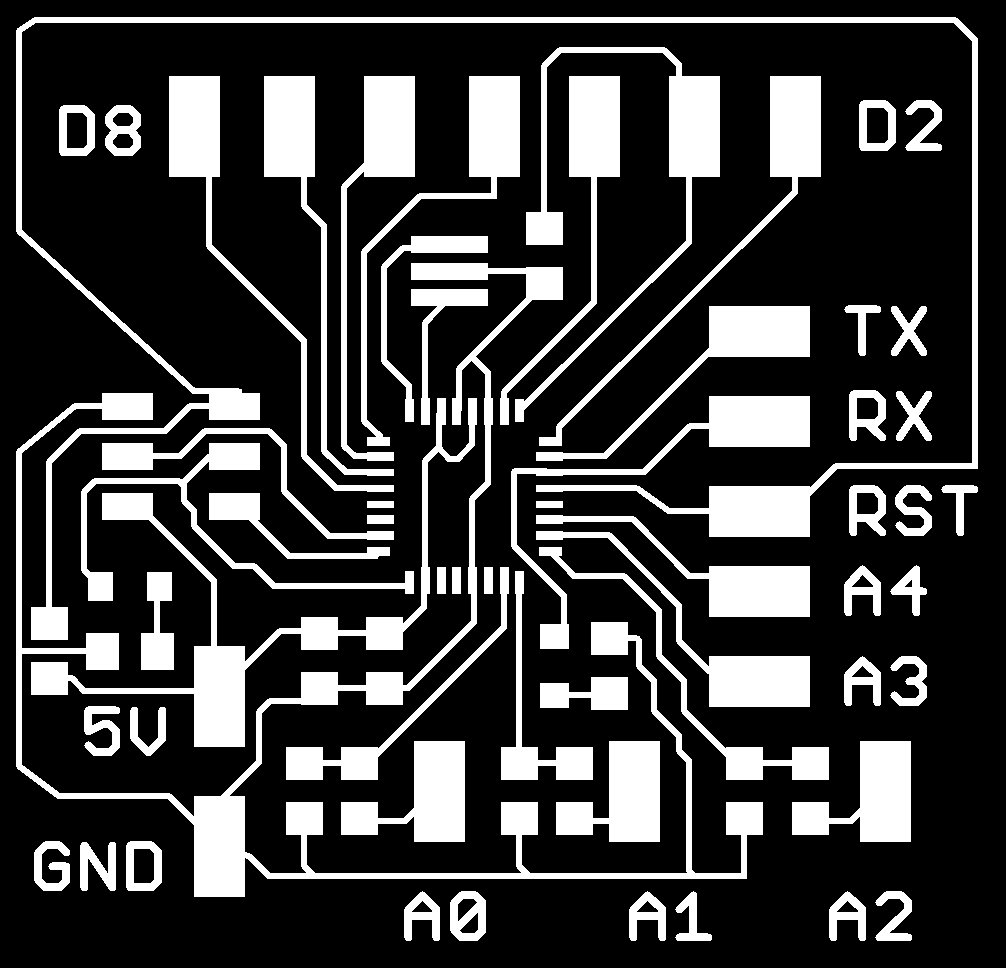

I will attempt to make much of the gimbal mechanism out of acrylic (freely available in the class), which has created some additional challenges (brittle, difficult to machine). I have also had some difficulty interfacing the COTS servos (full turn rotation) with the acrylic (requires screws). The electronics have also been challenging to design; the two modes of operation require a set of 'hardware controls' (knobs, LCD, switches), as well as a set of 'software controls' (GUI and serial communication). The most challenging aspect has been the software design, which requires that computations and servo commands be sent every 25ms while also supporting intermittent 2-way serial with the computer and 1-way serial with the LCD (stock ATmega's only have one hardware serial port.. and interrupt routines don't play well with software serial).

At the point I need to accomplish the following tasks:

Materials include 1/8" acrylic, 1/4" acrylic, 3 full-turn servos, FR1, SMD components, 2 switches, 3 LEDs, an LCD, 3 potentiometers with knobs, wire, FTDI cable, 2 1/6" steel pins, and 4 shaft collars. All have been purchased.

Cost is approx $100, primarily from Sparkfun and McMaster.